Turnkey installation and integration of AEI systems for mainline, gate, yard, loadout, storage, and inventory management. Single, double, and multiple track configuration along with scale, HBD, and DED interface. Host system integration, web access to data, and interoperability with connecting railroads, meets all AAR standards, and handles all train movement types.

Automatic Equipment Identification (AEI) Systems

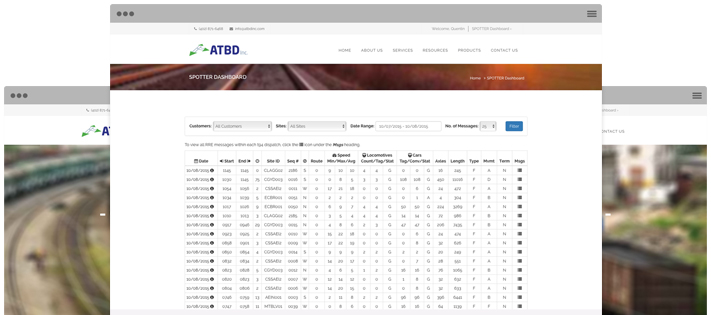

AEI Data Communication and Processing SPOTTER

SPOTTER is a data receiver of AEI data as reported by an AEI system or any AAR approved way side device meeting AAR data formatting standards. Records are collated and presented to the customer with a selection of sorting options including the ability to track and trace equipment within your database.

- Customer internet based access to data reported by your AEI system/s

- Database access to historical events and records

- Investigate or interrogate all of your AEI systems in one place

- Export data for internal use with employees or with customers

Transcore AP4118 AEI Tag Programmer

The AP4118 AEI Tag programmer is designed to encode data into the new AT5118 Transportation Tags. It cannot be used to encode data into the AT5110, AT5125, AT5510, AT5541 or AT5545 tags. These tags are encoded with the AP4110 AEI Tag Programmer.

The AP4118 AEI Tag Programmer also requires the AP5780 Permission Tag to encode tags. Permission tags will only be sold to organizations that have the Association of American Railroads M-1003 Quality Certification.

Transcore AT5118 Standard Rail Tag

Replacement tag for the AT5110 standard tag, requires new tag programmer AP4118.

AEI yard inventory reporting

ATBD will provide the field hardware, software, power, communications, and installation for data acquisition to support software developed providing for inventory management and the standing order of railroad equipment by track. The equipment deployed is TransCore based and meets AAR standards for operation and data formatting.

DTMF controlled Switch Machines

Radio controlled switch machines for yard and non-mainline applications are a good safe way to facilitate the continuous movement of trains by eliminating the need to stop, let off employees, throw the switch manually, and restart the movement. The implementation of this equipment at switches with heavy usage saves time, improves safety, and increases efficiencies.

DTMF Remote Switch Machine, Solar Powered

To improve your operating efficiency ATBD now offers remote controlled DTMF radio switch machines. By remotely controlling the operation of these switches we reduce the stopping of moving trains and eliminate the inherent safety issues of a manually thrown switch stand. Currently there are several manufacturers of this solution with varying features and capabilities. All systems have been approved by Class I Railroads.

DTMF controlled D-Rails

This application employs a version of the standard DTMF switch machine however, is used to throw and or apply d-rails be they bi-directional or switch point d-rails. Trail operators can stay on the engine and line the d-rail remotely. Additional communications can be added to provide for the operation of the switch machine from yard office.

AEI Hot Box Detectors

HBD systems in the field today can be upgraded to and integrated as AEI HBD and or new HBD can be ordered with AEI system integration off the shelf. Having AEI technology supporting a wayside detector allows for the positive identification of the defect car by providing the initial and number of the failed equipment. Further, historical performance data of a car can be managed over time to identify reoccurring, potential, and or pending problems. ATBD is well positioned to perform upgrades, integration, and complete turnkey systems.

Dragging Equipment Detectors

Used to protect important railroad infrastructure by detecting and reporting if equipment is traveling below the top of rail or even on the ground. These are fixed location detectors typically deployed ahead of bridges and structurers with ample distance to stop a moving train ahead of the protected structure. Simple and low cost, these systems have the potential of disproportional payback. ATBD can provide and install these systems with indicator lights, radio communication, and integrated with other systems.

DTMF Controlled Rail Gate

Our DTMF Controlled Rail Gate allows for the remote opening and closing of the rail gate via radio or pushbutton control. The gate is normally closed and can be operated by the connecting railroad via radio, pushbutton, remote radio, or automatically upon approach. Track circuits prevent the gate from closing while a train is present.

Industrial Crossing Application

As the focus on safety becomes more intense, areas of exposure become more clear. Companies look for ways to provide better and safer conditions for their employees and operation. One such area of focus are grade crossing where the simple stop sign or crossbuck no longer focuses or demands the attention of drivers. To provide a solution manufacturers have developed a simple Industrial Crossing system. These systems provide indication of approaching train movements and can be expanded to include railroad gates to better control road traffic. These systems do not fall under FRA Rules so their maintenance cost is reduced significantly. These system have a verity of options and features for the customer to choose from.

Video Inspection and Documentation

Video inspection and documentation has become an important part of business. The ability to combine AEI car identification technology with video documentation can eliminate any guess work of what car has arrived/departed, date, time, and combine this information with MB sized photos of the condition of the rail car, appliances, and even the seals. Improving your inventory management while avoiding potential litigation of exceptions is bundled into one solution. (See PDF for presentation materials)

Find what you're looking for

All Products

Automatic Equipment Identification (AEI) Systems

AEI Data Communication and Processing SPOTTER

Transcore AP4118 AEI Tag Programmer

Transcore AT5118 Standard Rail Tag

AEI yard inventory reporting

DTMF controlled Switch Machines

DTMF Remote Switch Machine, Solar Powered

DTMF controlled D-Rails

AEI Hot Box Detectors

Dragging Equipment Detectors

DTMF Controlled Rail Gate

Industrial Crossing Application

Video Inspection and Documentation